As a ‘one size fits all’ approach doesn’t work well when it comes to many products, particularly fans, ACI is able to offer a uniquely flexible approach to each and every customer specification.

Standard is not always best

Like many manufacturers, we have a number of standard ranges, providing for various volume and pressure ratios in a wide variety of construction materials including aluminium, mild steel, stainless steel, PTFE/Teflon coated and special paint finishes (such as C5M for offshore applications). We also offer a large choice of motor types, voltages, frequencies, speeds and manufactures.

However, providing a custom fan offer can provide many benefits to our customers and this includes significant cost-efficiencies and energy savings. For example, if a fan from a standard fan range is too small, it won’t be able to do its job properly. If the next size up is too big for that particular job, then the excess costs in energy alone could more than double the long-term costs of the fan.

So, for the greatest efficiency and best performance possible, the fan needs to be custom-designed specifically for the customer’s unique application. Whether it be a single unit order or a continuous requirement from a multinational OEM, ACI has the capabilities to assist with all application and customer types.

Designed from start to finish

We have made our process of specifying and ordering a custom-made fan simple. From concept to production, we’re here to provide a total solution addressing your requirements.

At the very heart of this, is our extensive and ongoing investment in design and manufacturing technology which has helped ACI to build a hugely experienced technical design department.

As well as providing modifications to standard products, the team are on-hand to support customers with any fan-related or drying/de-dusting issues that they may have. So even if you don’t have a full picture or a complete specification, they can work with you to design the perfect fan solution for the job. All they need to know is your desired outcome, plus a few key dimensions, and they will do the rest.

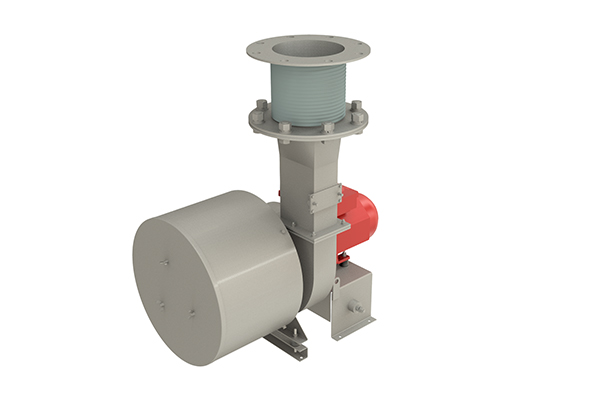

Once a specification has been agreed upon, our team of expert engineers develops a first stage design to share with you. Here at ACI, our experienced technical team use an array of design software including, Autodesk Inventor (for 3D modelling, drawings, basic rendering & animation), Autodesk Showcase (for rendering, animation, storyboards, etc.), and Autodesk AutoCAD Mechanical (for 2D CAD work). We also offer outline or assembly drawings and layouts along with 3D models, of any of our products and systems.

When considering the best solution for your requirement, our design engineers take into account all possible fan configuration, in terms of space restraint, material preferences, fan performance, inlet and discharge range as well as mounting alternatives.

With all these boxes ticked, our sales team can take you through your options, variants and the pros and cons of each, considering any additional factors that you might identify. Finally, when these steps have been completed, they can provide you with an accurate quote in terms of pricing and manufacture timeframes so that you’re always in control.

YEARS industrial Fan Expertise

Industry applications

CUSTOM FAN DESIGNS

SATISFIED CUSTOMERS

Real-Life Testing

From here, our technical team works on designing a prototype, using our dedicated in-house laboratory to test the model and give you absolute certainty that our advanced and innovative fan meets all your expectations.

Our fan testing capabilities can measure airflow, pressure and current and provide a performance curve to demonstrate your fan’s capabilities. It can also allow the implementation of original solutions to solve specific challenges or to address unusual requirements.

Our testing process is extensive – from reviewing performance, vibration, noise, speed, and including a heat run for three hours to measure the resistance across the windings from cold to hot, we ensure that the loading on the motor is correct. Any final changes can then be made before we send you the prototype for trialling in situ.

Many of our fan types can be manufactured to meet to both ATEX and IECEx regulations, and we also have an ISO 9001:2015 quality management system and ISO 14001:2015 certified factory. Furthermore, all ACI products are supplied with a full performance guarantee and carry the CE Mark to ensure complete customer satisfaction.

Fan requirement

technical specification

TECHNICAL DRAWINGS

DESIGN OPTIONS

PROJECT QUOTATION

IN-HOUSE TESTING

WHITE LABEL SOLUTIONS

We recognise how important it can be for an OEM to integrate technology and parts from third parties as a total, seamless solution, and in these cases, we can supply white label fans, which only includes a serial number for reference and maintenance.

Where we build solutions from the ground up, our customers also have the added reassurance that they own the IP, protecting their competitive advantage.

PRODUCT SERVICING

As part of our customer service, we work with clients across the world to update and replace fans, bringing them up to date with new regulations, increasing efficiencies and performance through new technology and materials implementation.

ACI also offer servicing and maintenance support for our all fan range.