INFORMATION

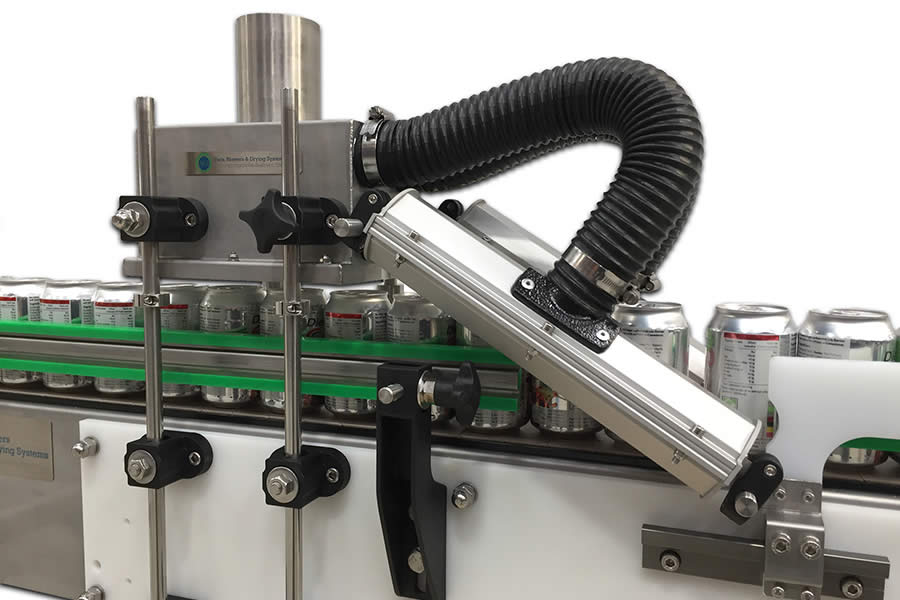

Cb-C – Craft Beer Can Drying System

ACI’s ‘Cb-C’ Craft Brewery Can Drying System is specifically designed to surface dry aluminium cans within craft and micro-brewery operations – whether drying for date coding or packaging. Using a small centrifugal blower, ACI’s ‘Cb-C’ system is suitable for line speeds up to 6,000 cans per hour. The system is designed to be easily installed, operated and maintained. They are capable of drying 330ml through to 568ml cans, giving a 96.5%* residual of water.

*figure attained after rigorous product testing at ACI’s test facility in Axminster.

Features include:

- A single slot can dryer mounted on top of the conveyor to dry lids or bottoms.

- Additional AK05 aluminium anodised air knives 300mm long (2x) to dry the can sides.

- ACI/EV APE711 (5.5kW) centrifugal blower, with a running current of 10.4A, and a motor FLC of 14A, providing an overall system pressure of 35inwg.

- Noise levels are 91 dB(A) without the polyethylene spray enclosure in place and 89dB(A) without.

- An additional acoustic enclosure is available for the blower.

Cb-B – Craft Beer Bottle Drying System

ACI’s ‘Cb-B’ Craft Brewery Bottle Drying System is specifically designed to surface dry glass bottles within craft and micro-brewery operations – whether drying them prior to labelling or packaging. Using a small centrifugal blower, ACI’s ‘Cb-B’ system has been sized for line speeds lower than 10,000 bottles per hour. The system is designed to be easily installed, operated and maintained and does not require any adjustment once installed. They are capable of drying all bottle sizes, giving a 98%* residual of water.

*figure attained after rigorous product testing at ACI’s test facility in Axminster.

Features include:

- Includes two Stainless Steel AKSM08 air knives 600mm long, mounted to the sides of the conveyor to dry the main body of the bottles, with additional ‘locline’ flexible nozzles to dry targeted areas such as the crown cap and neck areas.

- ACI/EV APE711 (7.5kW) centrifugal blower with a running current of 8.2A, a motor FLC of 14A, and provides an overall system pressure of 35inwg.

- Noise levels are 88 dB(A) and an additional acoustic enclosure is available for the blower.