If your supplier can’t test your process drying system before installation, how do you know whether you are paying too much for an over-engineered solution or worse for something that will not do the job?

The trick is to find the best value solution that effectively dries or cools while minimising both capital and running costs. It should not use more energy than is necessary and help you keep your carbon footprint down.

This is where having testing facilities such as our own helps you get it right.

There are numerous variables on a production line, and before we can design a system, we need to understand your application fully and if necessary, test our proposed solution. These variables include the production line speed, the size of the product and or conveyor system, how close the product can be to the dryers and how much drying or cooling you require. This information helps determine the type, size, position and number of air knives/nozzles needed.

Testing bespoke systems

Years of experience in manufacturing standard and bespoke systems will help us design a solution to meet your requirements. This knowledge is invaluable but having testing facilities means that we can prove that our proposed solution works and is the most efficient answer. When faced with the numerous variables of a production line, the only way to ensure this is to have data.

Armed with this understanding and data, we can customise our standard systems to meet different applications whether it is drying food cans or jars, spreading oil over pizza bread bases, or cleaning dust and swarf off precision engineered components for the automotive industry.

For the sake of your bottom line and to ensure that your system meets your requirements, which could be very different from a standardised solution, ask your supplier for proof and better yet observe the testing of it. After all, if it’s not tested and measured, how do you know that you have the best solution?

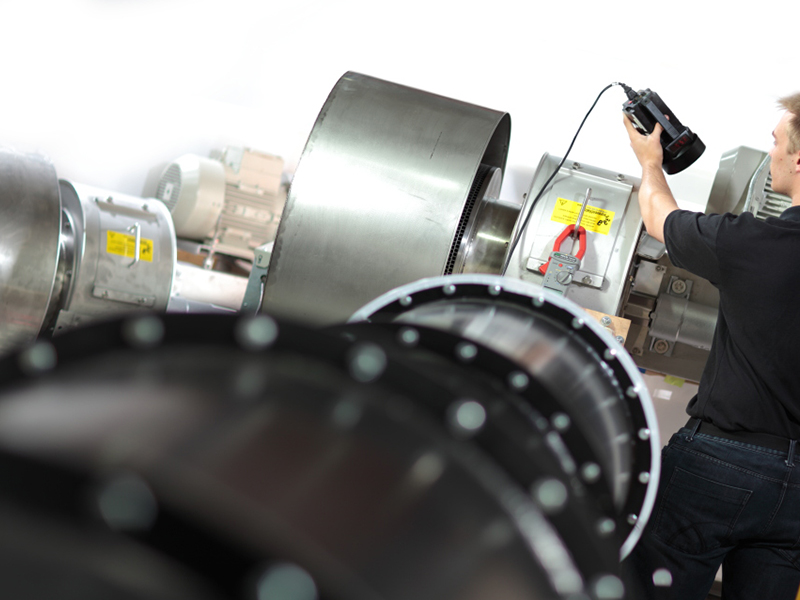

In our product testing facility, we can replicate your production line and test your product samples to ensure that our solution offers the best results in terms of capital cost and productivity.

Customers can visit to observe the testing and provide feedback or view it via a video link. More importantly, we can provide data and proof to show you the solution’s effectiveness. A typical product report may demonstrate how wet a sample was before processing and how much water the system removed.

This testing may also suggest more cost-effective alternatives. A system generally consists of a fan, motor, air knives/nozzles and/or jet plates. Changing these components may improve the system’s efficiency. For example, a smaller fan with a smaller motor may still achieve the desired result, reduce your running costs and cut your carbon footprint.

Precise measurement and data from running trials are the only way to measure and prove this for certain; otherwise, you rely on educated guesswork. Can you afford to take that chance?

LET US HELP YOU

You’re just a call or an email away from a total turnkey system solution that could help make your production line faster, or more efficient.