Enter Napoléon…

French military and political leader, Napoléon Bonaparte, is widely credited as being the driving force behind the invention of the can. In 1795, the French Military had a problem in need of a solution – long, vulnerable food supply lines. There was no effective method at this time for the preservation of food, transportation of food was difficult, and as many soldiers were dying from malnutrition and starvation as from enemy fire. Napoleon offered a 12,000 franc prize to any inventor who could devise a cheap and effective method for preserving large amounts of food.

It took over ten years for progress to be made. In 1806, Nicolas Appert, a French confectioner and brewer discovered that food cooked inside a jar did not spoil unless the seals leaked, and developed a method for sealing food in glass jars. This was a huge breakthrough – for the first time in history food could be preserved without obliterating its texture and destroying its taste. However, the process was slow and glass containers also presented issues for transportation. Unfortunately for the French army, the war ended before the process was perfected.

Ta Da! Voilà Le Tin Can…

Actually, the tin can wasn’t developed by the French at all, but by an Englishman who learned of Appert’s method and patented his ideas. Tin cans were preferable to glass jars as they were cheaper to produce and much easier to transport. Incredibly, each large can was hand-made, making the process labour-intensive and slow – even the best workman could only produce up to 60 cans a day. Additionally, the food could take up-to six hours to cook making this a very expensive process – too expensive for ordinary people. It’s hard to believe this now but canned food was actually a status symbol throughout the mid-nineteenth century, being something of a frivolous novelty.

The main market for the food at this stage was the British Army and Royal Navy. Can openers had not yet been invented so soldiers used to open tins with their bayonets or, failing that, smash them open with rocks.

Speeding Up Production…

Developments in can manufacturing started to come thick and fast in the latter half of the Nineteenth Century. In 1846 a gentleman called Henry Evans invented a die device that enabled production of cans to increase from a rate of 6 to 60 cans per hour (a far cry from what can be produced today, but still a good effort!) The first automatic can-making machinery was introduced in Britain in the late 19th Century, securing the tin can’s future in the preservation and packaging of food.

Canning of Beverages Becomes a Can-Do…

It wasn’t until 1930 that technology had advanced to the stage where beverages could be packaged in cans. Beer was available in cans from 1935 – closely followed by sodas, with their higher acidity and higher pressures. The key development for storing beverages in cans was the interior liner, typically plastic or sometimes a waxy substance, that helped to keep the product’s flavour from being ruined by a chemical reaction with the metal. The popularity of canned beverages was slow to catch on, as the metallic taste was difficult to overcome with the interior liner not perfected, especially with the more acidic sodas.

The first flat-top can appeared for sale in Richmond, Virginia. These cans were factory sealed and required a special opener called a ‘churchkey’ to consume the contents.

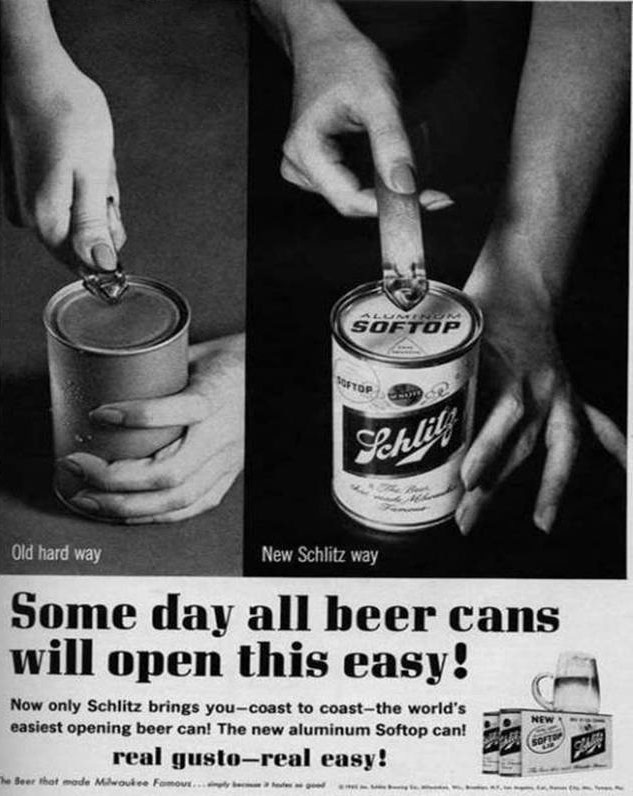

As shown in the advertisement (pictured left), can manufacturer Schlitz were pretty pleased with themselves when they developed the ‘soft-top’ can with an aluminium lid for easier opening. You still needed to use the churchkey, but apparently it required a lot less effort. “Some day all beer cans will open this easy!” – indeed!

Cone-Tops for the UK…

Flat-top cans didn’t make their way to the UK until 1950. Until this time, beverage cans in the UK had aesthetic similarities to a bottle – steel cans with cone shaped tops, sealed with crown corks. Because it was more akin to a bottle shape it could be filled using the existing equipment for bottles.

The next major development in can manufacturing came in 1958 when the first aluminium can was produced.

The Ring-Pull Invention…

In 1959, an American man called Ermal Fraze devised the can-opening method that would come to dominate the canned beverage market: the pull-tab. This invention had a huge impact on the popularity of cans as containers for beverages as it brought a new level of convenience to the consumer. The ring-pull eliminated the need for a separate opener tool by attaching an aluminium pull-ring lever with a rivet to a pre-scored wedge-shaped tab section of the can top. The ring was riveted to the centre of the top, which created an elongated opening large enough that one hole simultaneously served to let the beverage flow out while air flowed in.

The ring-pull design we have on our beverage cans today was introduced in 1989 for soft drinks, and 1990 for beer cans.

Recent & Future Advancements…

The last significant advancement in can manufacturing was in 1992 with the development of widget technology for cans of draught beer, and later for cans of cider in 1997. The widget device stores a tiny amount of gas released into the beer when the can is opened to form a creamy head – arguably one of the most significant innovations in can manufacturing in the second half of the 20th century.

Rumoured future technological advancements in beverage can manufacturing include experimenting with materials to keep beverages cool, LED technology on cans to display things like football results and the inclusion of Near-Field-Communication (NFC) technology which works as a promotional aid in conjunction with smartphones…!

More information…

Today, over 280 billion beverage cans are manufactured worldwide each year.

Some great resources on can manufacturing are the Can Manufacturers Institute website and the BCME Can Makers website. Alternatively, information on can manufacturing can also be found on the websites of leading can manufacturers: Crown Bevcan and Ball Packaging.

To learn more about ACI’s solutions for can manufacturing, please visit our Packaging & Labelling application page.

Solutions For Packaging & Labelling

Our range of bottle and can drying systems helps to ensure that today’s ground breaking labelling and packaging technology is not compromised by any surface water used in the packaging process.