INFORMATION

Benefits of dry crates / totes:

- Limit transfer line contamination

- Facilitate correct orientation

- Reduce risk of contamination

- Encourage better housekeeping

- Promote safer manual handling

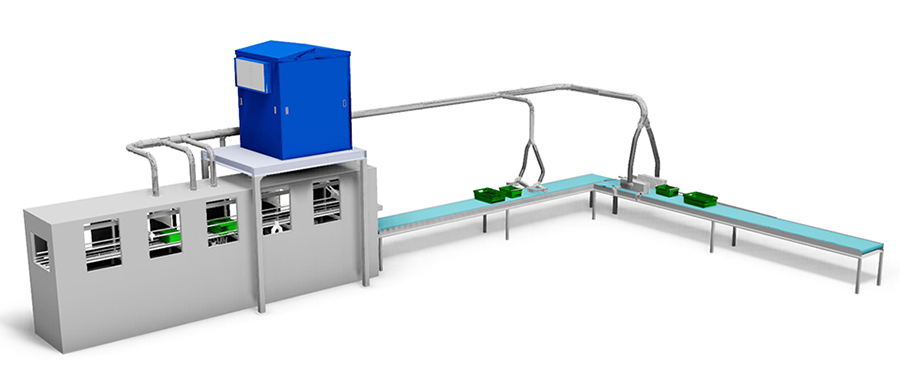

ACI’s proven crate drying systems are based upon the company’s blower-powered Air Knives. Blower power and Air Knife configurations are designed to match specific requirements regarding line speeds and crate/container/tote sizes.

Installation at NHS Depot

Blower Options

Due to the size of crate drying systems, ACI’s EV range of centrifugal blowers are the perfect solution to provide the air flow and pressure required to dry all shapes and sizes of crates and totes.

Crate Safety & Hygiene within the Food Industry

Good hygiene is obligatory in the food industry and installed systems must comply with appropriate hygiene standards to meet legal requirements. All systems must be designed to ensure that the food produced and distributed is of good quality and is safe for human consumption.

The hygiene standards for returnable and re-usable crates are critically important for protecting and maintaining bio-security. These crates travel repeatedly between the manufacturer, distributor and end-user and if not properly cleaned can act as carriers of contamination and unhygienic materials from food residues/deposits as well as from handling and storage processes.

Regular cleaning breaks the potential “cycle of contamination” as the crates travel continually between different locations. Proper crate drying helps to minimise the risk of the containers harbouring contamination after the cleaning process.

“Best practice” in the food industry recommends that transfer crates are washed, sanitised and dried between each trip from the distributor to the retailer or end-user.

Ideally crates should be washed and dried immediately after every use. They should not be accumulated nor stored in the open until washing takes place. Both practices increase the load of physical and bacterial contamination that needs to be removed by the washing process.

To discuss your crate drying application, contact us to speak to one of our sales engineers.